Electronics News

Archive : 11 February 2015 год

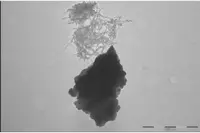

While nanostructured electrodes in Li-ion batteries have several advantages over bulk material electrodes, including shorter distances for charge-carrying particles to travel and a high surface area, battery researchers find it difficult to work with nanoscale materials. However, researchers at the University of Maryland, Baltimore County (UMBC) have isolated a peptide which binds strongly to nanosized particles of lithium manganese nickel oxide (LMNO), improving the potential power and stability of the compound when used as an electrode.

While nanostructured electrodes in Li-ion batteries have several advantages over bulk material electrodes, including shorter distances for charge-carrying particles to travel and a high surface area, battery researchers find it difficult to work with nanoscale materials. However, researchers at the University of Maryland, Baltimore County (UMBC) have isolated a peptide which binds strongly to nanosized particles of lithium manganese nickel oxide (LMNO), improving the potential power and stability of the compound when used as an electrode.

"Biology provides several tools for us to solve important problems," said Evgenia Barannikova, a graduate student at UMBC. "By mimicking biological processes, we can find the better solution."

Barannikova and her colleagues used a procedure called 'Phage Display' to screen more than 1billion possible peptides in search of one that would stick strongly to LMNO. The researchers then combined the newly discovered peptide with a previously isolated peptide that binds to carbon nanotubes, which can serve as conductive nanowires in Li-ion electrodes.

The resulting peptide could form a bridge, binding to LMNO nanoparticles and to carbon nanotubes, keeping them close enough to maintain a connection through multiple charging cycles. In this way, the researchers expect the peptide will improve the power and cycling stability of future Li-ion batteries, allowing them to be smaller and maintain longer lifetimes.

Now, Barannikova plans to make an anode using similar techniques and to integrate the two components.

Author

Graham Pitcher

Source: www.newelectronics.co.uk

ARM saw a 19% increase in revenue for Q4 2014 compared to the same quarter in 2013, according to its latest financial statement. Other positives highlighted by the company included an increase in processor licensing revenue of 30% and what it says is a record cash generation figure of £122million.

ARM saw a 19% increase in revenue for Q4 2014 compared to the same quarter in 2013, according to its latest financial statement. Other positives highlighted by the company included an increase in processor licensing revenue of 30% and what it says is a record cash generation figure of £122million.

Simon Segars, chief executive officer, said: "2015 will bring exciting opportunities and challenges as ARM invests in new products and technologies and continues to establish itself in competitive new markets."

The company says the outlook for royalty revenues in 2015 is 'encouraging'. In its financial statement, it said 'we anticipate that total group dollar revenues for Q1 will be up about 10% year on year, based on strengthening royalty revenue growth, and our expectation of the profile of licence revenue through the year'.

The company signed 53 processor licences in Q4 2014, taking the total signed in the year to 163, with 15 for Cortex-A series processors. Activity is said to be high in China and Korea. Meanwhile, 23 licences were signed in Q4 for Cortex-M class processors.

Pete Hutton, president of ARM's product groups, said he was 'really pleased' with the quarter. "There was a big uptick in licensing and it was a record quarter for licensing revenue and for licenses closed. It shows there is growing demand out there for ARM technology."

According to Hutton, there were 11 new licensees amongst the 53 companies who signed deals in Q4. "They range from small microcontroller start ups to large OEMs," he added.

Also included in the list are five licenses for two forthcoming cores – codenamed Teal and Grebe – which appear to be based on a variant of the company's v8 architecture targeted specifically at MCUs. According to ARM, Teal and Grebe are 'designed for energy efficient and secure embedded applications from smart automotive to wearable technology'.

Author

Graham Pitcher

Source: www.newelectronics.co.uk

Shopping trolleys fitted with low cost sensors and Bluetooth Smart technology could revolutionise the retail experience, says Cambridge Consultants, pinpointing the location of trolleys within stores to within 1m and alerting shoppers to promotions as they browse the aisles.

Shopping trolleys fitted with low cost sensors and Bluetooth Smart technology could revolutionise the retail experience, says Cambridge Consultants, pinpointing the location of trolleys within stores to within 1m and alerting shoppers to promotions as they browse the aisles.

The innovation is a small device that fits on a trolley wheel and which harvests energy from the wheel's rotation.

Dipak Raval, a commercial director at Cambridge Consultants, said: "Customers are increasingly frustrated by queueing times in stores – and often reluctant to download apps in order to get the best out of their shopping experience. Our low cost technology is easily combined with existing retail equipment to improve efficiency for both the retailer and the customer."

The 'smart' trolley could interact with customers during a shopping trip; for example, passing on discount vouchers based on where they are in the supermarket. It could also map the most efficient route through a store, based on each customer's shopping list.

As well as enabling stores to target customers with relevant offers as they shop, data from smart trolleys could also be used by retailers to understand better what their customers decide not to buy.

Author

Graham Pitcher

Source: www.newelectronics.co.uk

Organic electronic materials specialist Merck and flexible electronics company FlexEnable claim they have reached an important stage in the development of plastic LCDs. Between them, the companies have created a demonstrator in what is said to be a 'very short timeframe' and which is said to show a route to low cost solutions for volume manufacturing.

Organic electronic materials specialist Merck and flexible electronics company FlexEnable claim they have reached an important stage in the development of plastic LCDs. Between them, the companies have created a demonstrator in what is said to be a 'very short timeframe' and which is said to show a route to low cost solutions for volume manufacturing.

Organic electronic materials specialist Merck and flexible electronics company FlexEnable claim they have reached an important stage in the development of plastic LCDs. Between them, the companies have created a demonstrator in what is said to be a 'very short timeframe' and which is said to show a route to low cost solutions for volume manufacturing.

"We are very happy about this step forward as it clearly shows the enormous innovation potential the LC technology holds for us to explore," said Inese Lowenstein, head of Merck's Display Materials business unit. "It also shows that plastic based bendable – or even flexible – displays are not a dream and encourages us to develop new LC modes especially, for this application. Now we can also imagine how the size of LC displays can grow even further, by making them lightweight, transportable and unbreakable."

Referring to the demonstrator, Indro Mukerjee, FlexEnable's chairman, added: "To achieve this within months, rather than years, is a testament to the depth of understanding and IP we have across our toolkit of industrially proven processes. Plastic LCDs bring clear benefits where weight and thickness is key – including volume consumer and industrial markets. It also offers a route to simpler, lower cost device stacks for display makers."

The project, cofunded by the seventh Framework Program of the European Union, also involved the University of Stuttgart, LOFO High Tech Film, Micro Resist Technology and Etkes and Sons.

Author

Graham Pitcher

Source: www.newelectronics.co.uk